Petroleum Products

Solvents

Organic solvents have many applications in chemical, metal, and electronic industries, as well as in many consumer products such as coatings or paints. Therefore, they are considered among the most important chemicals.

Choosing quality and cost-effective petrochemical solvents is necessary for the country's industries.

Definition of Solvents

The solvent is derived from the Latin word solvō, meaning to dissolve. In fact, a solvent is a substance that dissolves a solute and thus creates a solution.

A solvent is usually a liquid but can also be a solid, a gas, or a supercritical fluid. When one substance dissolves in another substance, a solution is formed. This is due to the fact that compounds such as sand are not soluble in water. All substances are uniformly distributed at the molecular level in a solution, and no residue remains.

Petrochemical Solvent

The petrochemical solvent is a chemical product produced from oil through refining. Some of the chemical compounds from petroleum are also obtained from other fossil fuels such as coal or natural gas or renewable sources such as corn, palm fruit, or sugarcane. These solvents have many applications in industry, agriculture, paint, glue, and plastic. The type of application of solvents has a strong dependence on their tendency to evaporate. Petrochemical solvents have always been classified based on their boiling point.

- White Spirit

- kerosene (Krozny Solvent)

- Spirit with Specific Boiling Point (SBP)

- Pure aromatics (benzene, toluene, xylene, and monoethylene glycol)

1. White Spirit

White spirit is a heavier solvent than spirit with a specific boiling point. Its boiling point is in the range of 135 to 205 degrees Celsius. Solvent 402 and Solvent 403 are examples of these spirits. These solvents are widely used in paint thinners.

2. Kerosene (Krozny Solvent)

Kerosene solvent is used in the printing industry, lighting, and emergency lighting. Its boiling range is between 160 and 300 degrees Celsius.

3. Sprite with a unique boiling point

The boiling range of SBP is between 30 and 160 degrees Celsius.

4. Pure Aromatics (benzene, toluene, xylene, and monoethylene glycol)

Benzene, toluene, xylene, and mono ethylene glycol are essential and primary aromatic substances used in the oil and petrochemical industries. Considering the importance of these materials, we will explain them.

4.1. Benzene

Benzene is known as the simplest aromatic compound, and despite the harmful effects it can have on the human body, due to its special molecular structure, it is widely used. Benzene is used in the manufacture of rubber and tires, the printing and paint industry, the production of resin, glue, nylon, styrene, and in the combination of industrial solvents to remove grease and fat from various surfaces.

4.2. Toluene

Toluene is a clear and colorless liquid with a specific smell. This solvent easily dissolves other substances in it. Toluene occurs naturally in crude oil and the Tulu tree. This substance is produced in the process of making gasoline and other fuels from crude oil, in the production of coke from coal, and as a byproduct in the production of styrene. Toluene is used in producing paint, paint thinner, nail polish, glue, rubber, and the printing industry. And it is added to gasoline along with benzene and xylene.

4.3. Xylene

Xylene is one of the most critical and central petrochemical products. This petrochemical substance is a colorless, transparent, volatile liquid with a pleasant smell. It is obtained from the carbonization of coal during coke fuel production. This compound has many applications in the production industry of waterproof coating, transmission line pipes, as a supplement in gasoline, glue, polishes, and ink. Xylene consists of a benzene ring and two methylene groups.

Since the methylene group can be moved by changing the location of the methyl group on the benzene ring, we can also know it by the names meta-xylene, para-xylene, and ortho-xylene. This is if the general name of this substance is dimethyl benzene, regardless of the placement of methylene.

Long-term exposure to xylene causes bloating, nausea, burning (eyes, nose, and throat), fatigue, headache, discomfort (liver, stomach, and kidney,) and breathing disorders.

4.4. Monoethylene glycol

Monoethylene glycol (MEG), or antifreeze, is a toxic chemical substance with the chemical formula C2H6O2 and a molecular mass of 62.07 g/mol, which has various applications in the preparation of polyester fibers, fabric, polyethylene terephthalate, antifreeze, oil, gas, and cooling industries. Low viscosity and high heat transfer properties compared to other chemicals are essential advantages of using this material in antifreeze.

Monoethylene glycol is a thermodynamic inhibitor in the oil and gas industry. Adding this substance to natural gas prevents system corrosion, hydrate formation, and freezing in pipelines. Despite the advantages offered, ethylene glycol can be toxic if consumed. The sweet taste of monoethylene glycol quickly attracts children and animals. As it has been said, this substance is highly toxic, so it should be kept and stored in appropriate places out of the reach of children.

Uses of aromatic solvents

These solvents are widely used in the following applications.

- As a solvent and chemical mediator

- In the preparation of chemical raw materials

- In the lubricant

- In detergents

- In the cleaner

- In pharmaceuticals

Introduction of chemical solvents required by the industry

A. Adhesive and coating industry

Adhesives and sealants are produced from different polymers. Their selection and their combination use the choice of the appropriate chemical solvent. Most chemical solvent systems are designed to optimize the solubility of the primary polymer. Adhesives can be divided into those formed by chemical reaction reactions bonded due to physical processes.

Chemical reactive adhesives are divided into three categories based on the production method: polymerization, polyaddition, or polymer condensation. Physical bonding adhesives include pressure-sensitive and contact adhesives, melt or solution adhesives, and plastics. Polymerization adhesives from cyanoacrylate (without solvents), anaerobic adhesives (which do not contain solvents but require plastic primers and some metals that are copper naphthalene solutions), and adhesives that can be used against ultraviolet rays (polyurethane solvent-free compounds) and epoxy) need.

Contact and pressure-sensitive adhesives are made of various polymers, including acrylic acid esters, polyisobutylene, polyesters, polychloroprene, polyurethane, silicone, styrene-butadiene copolymer, and natural rubber. Except for acrylic acid ester adhesives, which can be processed as solutions, emulsions, UV 100% solids, and curable silicones (which may only be traces of solvents), all residual rubbers are primarily in significant quantities. They are made from solvents such as hydrocarbon solvents (mainly heptane, hexane, and naphtha), ketones (mainly acetone and methyl ethyl ketone), and aromatic solvents (mainly toluene and xylene).

Melt adhesives and plastisols do not contain solvents. The group of soluble adhesives includes products prepared from the following polymer solvent systems: nitrocellulose (common solvents include solvent compounds usually of a ketone or ester, alcohol, and a hydrocarbon selected from isopropanol, 2-butylhexanol, amyl acetate, acetone, methyl ethyl ketone), nitrile rubber (the primary solvent – methyl ethyl ketone), polychloroprene (usually in a mixture of solvents including ketones or esters, aromatic and aliphatic organic hydrocarbons from naphtha, hexane, acetone, methyl ethyl ketone, benzene, toluene and polyvinyl acetate (water) dissolve.

B. Asphalt industry

Numerous construction products are made from asphalt and coal for applications such as drive sealer, asphalt cutter, cement, concrete primer, cold mix concrete, roofing cement, joint expansion filler, patch fluids, waterproofing, disinfectant liquid membranes, and pipe coating. All these products contain chemical solvents. The most straightforward formulation is a mixture of asphalt and (usually) mineral oils used for sealing, priming, and coating concrete. The most technologically advanced products are used for waterproofing and pipeline coating. These products are also based on the dispersion of asphalt in a chemical solvent but reinforced by adding a polymer. The addition of polymer modifies the plastic behavior of asphalt and makes it elliptical. Usually, additional chemical solvents are added to improve solubility in polymer components.

Reactive polyurethanes are often used in the waterproofing modification of liquid membranes. Toluene and xylene are asphalt compounds often used as additional chemical solvents.

These materials partially solidify due to the evaporation of the solvent. Their elastomeric properties result from chain extensions and cross-chain reactions that form an internal polymer network that reinforces the asphalt.

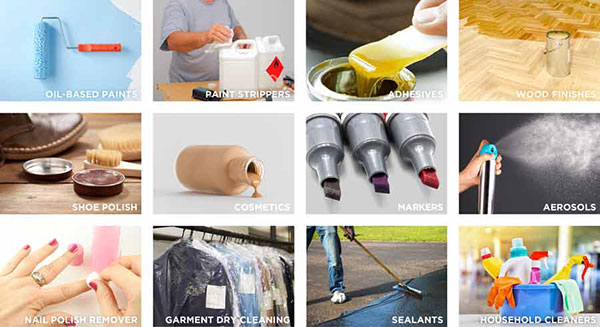

C. Cosmetics industries

Several cosmetic products contain solvents. These include nail polish, nail polish remover, perfume, hair dye, general cleaners, hair spray, and lotion. In most cases, ethanol is the only chemical solvent. Nail polish and nail polish remover contain many types of chemical solvents.

Nitrocellulose, polyester, acrylic ester and methacrylic ester copolymer, formaldehyde resin, and cellulose acetate butyrate are the most common polymers in nail polish formulations. Solvents were selected according to the polymer used. Solvents include acetone, methyl acetate, ethyl acetate, butyl acetate, methyl glycol acetate, methyl ethyl ketone, methyl isobutyl ketone, toluene, xylene, isopropyl alcohol, methyl chloroform, and naphtha. Solvents make up the bulk of the composition, usually around 70%. Modification is being done to improve the flexibility and durability of the nail polish.

Other efforts have been made to improve antifungal properties, remove ketones and formaldehyde resins (ketones because of their toxicity and irritating odor, and formaldehyde resins because they contribute to dermatitis), and eliminate jaundice. Acetone used to be the only effective chemical solvent for many nail polish removers. It is still used, but there is a current effort to eliminate the use of ketones in nail polish removers. The most used compounds are isopropanol/ethyl acetate and ethyl acetate/isopropanol/1,3-butanediol.

Common cleaners used in hairdressing salons contain isopropanol and ethanol. Hair spray contains ethanol, a combination of ethane, propane, isobutane, and butane.

Chemical exposure in hairdressing salons, although there is a high concentration of ethanol, the detected level is below the NIOSH limit. Concentrations in non-ventilated halls (about 3 times higher) than those measured in air-conditioned halls. Small concentrations of toluene are also found, which probably originates from paint components.

Organic chemical solvents in microbial production stages

Chemical solvents are not compounds found on Earth. In natural conditions, their presence in significant amounts is limited to certain areas. Only a limited number of chemical solvents are of biological origin, and some may reach higher concentrations in nature. The best-known example is ethanol. However, butanol and acetone are also readily formed by microbes, and high concentrations may occur. In fact, at the beginning of the 20th century, extensive production facilities were in operation for the microbial production of butanol and acetone. In addition, terpenes are natural solvents mainly produced by plants and can reach high concentrations locally. For example, limonene is found in tiny droplets in orange peels. All these chemical solvents are toxic to microbial cells.

Development in microbial industry through chemical solvent

With the development of the chemical industry, this picture has changed dramatically. In contaminated sites, microorganisms may be exposed to high concentrations of many chemical solvents. With only a few exceptions, it turned out that microbes are able to degrade these compounds if the concentration is low. This degradable potential is not unexpected given the rare amounts that may exist locally in the natural biosphere. But exposing cells to abnormally high concentrations of these solvents usually results in irreversible inactivation and eventual death.

The chemical industry is based mainly on chemical solvent-based processes. But in biotechnological processes usually, microbes are exploited in a water-based system. This approach is quite understandable given the preference of microbes for water and the chemical solvent problems for whole cells. Chemical solvents are often used to extract products from the aqueous phase, but only after the manufacturing process is complete. At this stage, damage to whole cells does not matter. In both the chemical and biotechnology industries, organic solvents have many advantages over water due to the product’s or substrate’s nature. As a result, many opportunities for using chemical solvents in biocatalytic processes have been investigated during the past decades: the simpler the biocatalytic system, the more complex the use of chemical solvents.

Get all the necessary information to order and buy the best Iranian solvents by contacting our colleagues at Iran Petroleum.

Comments (2)

Hello sir I need Irani solvent zero smell in punjab please contect my what’s app +923227040491

Hello,

Dear MR.Rabish,

Thank you for your message.

Please send us your official application via company email on your letterhead with the company stamp. Specify the quantity, destination and type of delivery.

Best regards,

Iran Petroleum